Disposable gloves have actually ended up being a sign of safety, but they can inspire a false sense of security. Making use of disposable gloves should be an enhancement, not a replacement, for correct hand cleaning. Disposable gloves are simply that- made for a solitary usage. The longer gloves are worn, the most likely their effectiveness as a barrier will deteriorate. Disposable gloves production lines manufacturer will give you some suggestions.

1. Foodservice gloves

A terrific guideline to follow is to change gloves whenever you are dealing with a brand-new active ingredient. For instance, altering gloves after managing raw meat or fish and grabbing a new pair prior to preparing a fresh salad. This assists to stop the cross-contamination of germs from various other foods and also promotes a safe and sanitary setting.

Gloves ought to also be altered after carrying out various other jobs such as cleansing to stop chemicals or bacteria from coming in getting in touch with food. Although, employees need to wear gloves while cleaning to avoid hazardous microorganisms that can be found in contact with bare hands.

Food allergic reactions are an additional big issue while working in kitchens or preparing food. Gloves need to be switched over prior to working with dishes going to customers with allergies or concerns.As a general policy, gloves need to be transformed every two hours.

2. Medical gloves

It is important to note that some patients might be allergic to latex medical/exam gloves, and if that holds true, latex-free alternatives, such as nitrile or vinyl gloves ought to be used. Medical gloves should always be made use of throughout contact with a client and also must not be eliminated till after examinations or contact with a client is completed. The exact same glove needs to not be utilized to perform exams or care on several individuals to prevent the spread of damaging germs or pathogens. Gloves must additionally be worn prior to procedures to maintain settings sterile.

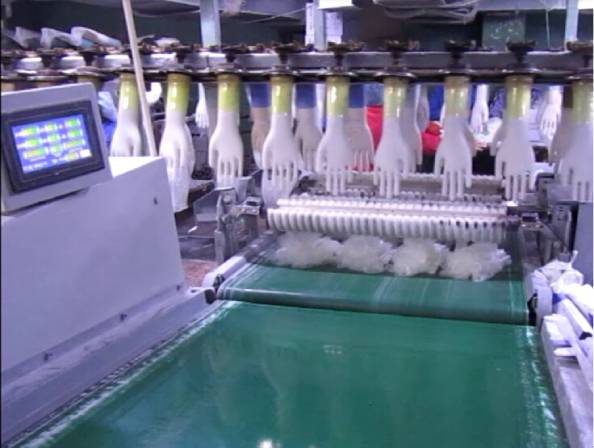

Disposable Gloves Production Lines

3. Exactly how to put on and also take off gloves

Unless contaminated, disposable gloves can be dealt with the general waste, ideally a closed container. A closed container is a container with a fitted lid. Where the gloves are contaminated, they should be disposed of in a shut container, ideally, one that does not need to be touched to the area infected gloves inside. A bin with a foot pedal or various other hands-free systems to open up the cover would certainly be appropriate.

The bin for polluted disposable gloves ought to have 2 container liners to guarantee the waste is double nabbed. Dual bagging reduces any type of exposure to the individual dealing with the waste.

4. Tips

A. Always bear in mind that just using gloves is not nearly enough to prevent the spread of foodborne health problems in food solution setups or the virus in medical setups. Always ensure hands are washed before and also after using gloves, this includes washing hands before placing on a new pair of gloves. These assist stop bacteria that might have can be found in contact with bare hands from dispersing.

B. Hand protection need to also be examined or slits or splits prior to wearing, and also must be quickly removed if they are ripped or torn while in use. It is important to watch on disposable gloves, specifically while making use of sharp objects, and also to make certain hands are cleaned thoroughly before wearing a brand-new set and also continuing tasks.

C. Finding gloves that are the right size is likewise necessary to protecting against the spread of germs and also avoiding holes or tears. Gloves that are too limited might tear conveniently, and gloves that are too loose might not offer appropriate insurance coverage or defense. Fortunately, Fengwang Machinery provides Disposable Gloves Production Lines in a range of dimensions, so you can locate simply the right dimension to suit your requirements.

D. Disposable gloves shouldn't be cleaned, recycled, or shared amongst workers after use as they are developed for single-use, and washing might trigger damage or prove inefficient at getting rid of unsafe microorganisms.

For more information about producing single-use gloves, please contact with disposable gloves production lines manufacturer.